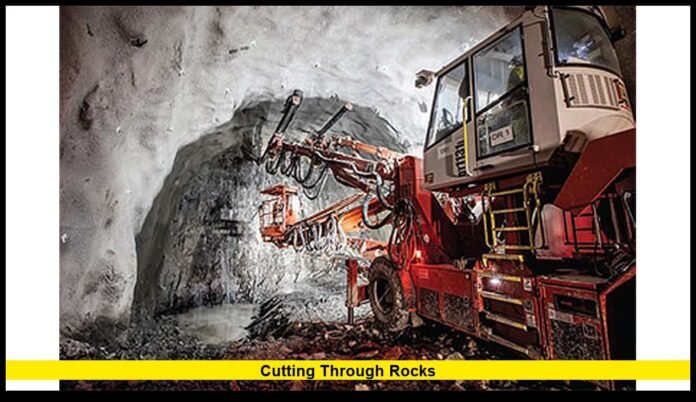

Cutting through rocks has become more advanced and efficient than ever in 2026. Across the United States, industries from mining to construction are using precision machinery and intelligent systems to cut through stone with speed, safety, and minimal environmental disruption. What was once a labor-intensive, time-consuming process now combines robotics, diamond-based tools, and automation to transform how America builds and extracts its natural resources.

These innovations are changing everything from highway tunnels and clean-energy projects to geological research. Companies across the U.S. are replacing traditional drilling and blasting with quieter, cleaner, and more accurate rock-cutting solutions that meet modern safety and sustainability standards.

How Cutting Through Rocks Shapes Modern Industry

The process of cutting through rocks is fundamental to several major U.S. industries. It plays a key role in:

- Mining and mineral extraction, where efficiency directly impacts national production.

- Infrastructure and transportation, especially tunnel construction, rail expansion, and highway upgrades.

- Renewable energy projects, including wind, hydro, and geothermal installations.

- Geological research, where precision tools help scientists extract samples safely.

Today’s rock-cutting technology combines mechanical engineering, materials science, and data analytics to improve both performance and environmental outcomes.

The Tools Used in 2026 for Cutting Through Rocks

Modern rock cutting isn’t a single method—it’s a collection of specialized systems designed for different hardness levels and project types. These include:

1. Diamond Wire Sawing

A steel wire embedded with industrial diamonds rotates at high speed to slice through hard surfaces like granite and marble. Diamond wire sawing is now standard in mining quarries and construction sites for its low vibration and high precision.

2. Tunnel Boring Machines (TBMs)

TBMs have become a symbol of large-scale infrastructure. These massive rotating machines grind through rock to create tunnels for transportation and utilities. Modern TBMs used in the U.S. feature electric drives, real-time mapping sensors, and dust control systems.

3. Water Jet Cutting

This method uses ultra-high-pressure water mixed with abrasives to cut through rock without generating heat or causing microfractures. It’s especially popular for delicate operations where surrounding materials must remain intact.

4. Hydraulic Rock Splitters

Hydraulic systems apply controlled pressure to create clean fractures. This technique is widely used in confined construction areas where blasting is not feasible.

5. Laser and Plasma Cutting (Emerging Technologies)

While still limited to research and niche applications, laser and plasma-based systems are being tested in specialized mining and defense projects for their precision and reduced tool wear.

Each method has distinct strengths. Selecting the right one depends on the rock’s hardness, depth, and the project’s environmental and safety requirements.

Advancements Transforming Rock Cutting in the U.S.

Technology has reshaped how America approaches cutting through rocks. The biggest advancements in 2026 focus on automation, durability, energy efficiency, and sustainability.

Automation and Robotics

AI-powered robotic cutters are revolutionizing excavation. These machines can assess rock hardness, adjust cutting speed, and detect fault lines automatically. In Nevada’s lithium mining operations, automated cutting units now operate with minimal human intervention, improving precision and reducing injury risk.

Improved Diamond Composites

Industrial diamond remains the hardest material known, but recent innovations have strengthened it further. Manufacturers have introduced synthetic diamond composites that resist temperature damage and extend tool life, making them ideal for continuous operations in mining and tunneling.

Electric and Hybrid Equipment

To reduce emissions, U.S. companies have started replacing diesel engines with electric-powered cutting machines. Hybrid systems lower carbon output while maintaining the torque required for deep rock penetration.

AI-Driven Monitoring Systems

Sensors and data analytics tools monitor tool performance, rock density, and vibration in real time. This feedback helps crews fine-tune equipment on the spot, saving both energy and resources.

Noise and Dust Reduction

One of the major goals of 2026 technology is minimizing noise and dust during rock cutting. Enclosed cutting heads, water misting systems, and dust extraction units have become standard in most urban and underground projects.

Industries Relying on Rock Cutting

Cutting through rocks plays a vital role in shaping the nation’s infrastructure and resource supply. Let’s look at where these technologies are making the most difference today.

1. Mining and Resource Development

In the mining industry, precision cutting reduces waste and increases productivity. States such as Arizona, Utah, and Nevada—home to large copper, lithium, and gold reserves—have seen major investments in continuous rock-cutting systems that eliminate the need for blasting.

These systems not only improve mineral recovery rates but also protect nearby communities by reducing vibrations and air pollution.

2. Infrastructure and Transportation

Cities like Los Angeles, New York, and Seattle are expanding underground transit systems that depend on high-performance tunnel boring machines. These machines cut through mixed rock formations while minimizing disruption to the surface above.

By combining geological mapping and AI, engineers can plan cutting paths that avoid weak zones and ensure long-term tunnel stability.

3. Renewable Energy Construction

Clean-energy expansion across the U.S. has driven the demand for precise rock excavation. In Texas and Colorado, engineers use rock-cutting machines to prepare stable foundations for wind turbines and solar installations on rocky terrain.

In hydropower and geothermal projects, controlled cutting enables deep drilling and tunnel creation without harming water tables or geological formations.

4. Civil Engineering and Building Projects

From road expansion to high-rise construction, controlled rock cutting ensures stable foundations in regions with hard bedrock. Hydraulic splitters and wire saws are commonly used in urban development, where precision and safety are priorities.

5. Scientific and Geological Research

Research institutions use micro-cutting tools to analyze rock cores for environmental and archaeological studies. The Smithsonian and U.S. Geological Survey labs employ diamond saws and water jets to prepare rock samples without altering their structure.

Environmental and Safety Standards

As environmental awareness grows, rock cutting has become cleaner and safer. The Occupational Safety and Health Administration (OSHA) and Mine Safety and Health Administration (MSHA) enforce strict guidelines covering air quality, vibration control, and equipment maintenance.

Some of the most significant improvements include:

- Real-time air monitoring systems that track silica dust levels.

- Water recycling systems to reduce freshwater use during cutting.

- Sound barriers and enclosures to limit noise in residential zones.

- Remote control operation for safer management of underground machines.

Electric-powered systems are also reducing carbon emissions, aligning with state and federal sustainability goals.

Economic Importance of Rock Cutting in the U.S.

Cutting through rocks directly supports the country’s industrial backbone. The rock excavation and equipment industry now contributes billions annually to the U.S. economy.

Industry data from 2025–2026 shows that:

- The U.S. rock-cutting machinery market surpassed $1.8 billion in annual revenue.

- Growth is being driven by federal infrastructure investments and renewable energy expansion.

- Employment in the construction and mining machinery sector continues to rise, especially in states with major development projects.

These numbers demonstrate how advancements in rock-cutting efficiency translate into national economic growth.

Comparing Rock-Cutting Methods

To understand the evolution of the industry, it helps to compare how different technologies perform today:

| Method | Primary Use | Precision | Cost Efficiency | Environmental Impact |

|---|---|---|---|---|

| Diamond Wire Saw | Quarrying, construction | High | Moderate | Low |

| Water Jet Cutting | Research, delicate work | Very High | High | Very Low |

| Tunnel Boring Machines | Transportation tunnels | Moderate | High | Moderate |

| Hydraulic Splitting | Controlled demolition | Moderate | Low | Low |

| Laser-Assisted Cutting | Industrial applications | Very High | High | Very Low |

This table shows that while diamond and water-jet systems lead in precision, TBMs remain essential for scale and productivity.

Training and Workforce Development

Operating modern rock-cutting equipment requires technical expertise. Companies now invest heavily in worker training programs focused on machine automation, safety, and maintenance.

Trade schools and engineering programs in states such as Colorado, Arizona, and Pennsylvania have introduced specialized courses in rock mechanics and excavation technology. These programs prepare technicians and engineers for high-demand roles in construction and mining sectors.

Many employers also provide remote operation training, allowing workers to control machines from secure command centers—a growing trend in underground projects.

Challenges Facing the Industry

Despite technological progress, several challenges persist in 2026:

- Equipment wear remains a costly issue in hard rock environments.

- Energy consumption is still high for large-scale tunnel projects.

- Supply chain delays occasionally affect specialized tool components.

- Environmental compliance costs continue to rise as regulations tighten.

However, most experts agree that ongoing innovation—particularly in material science and electric-powered systems—will help mitigate these challenges.

Future of Rock Cutting in America

The future of cutting through rocks lies in AI integration, sustainable energy use, and data-driven engineering. Researchers and manufacturers are already testing new technologies, including self-calibrating cutters, fully electric TBMs, and laser-assisted excavation systems designed for deep-earth projects.

These advancements aim to reduce downtime, improve safety, and extend machine life. As the U.S. continues investing in renewable energy, infrastructure modernization, and resource development, the demand for precise and efficient rock-cutting systems will only grow.

In conclusion, the technology driving cutting through rocks in 2026 represents a balance between innovation, sustainability, and safety. From lithium mines in Nevada to subway tunnels in New York, precision cutting tools are helping America build its future—one layer of rock at a time.

What do you think is the most impressive innovation in rock-cutting technology today? Share your views below.